Efficient water treatment for humidification and a wide range of applications

Tap water is one of the best protected foodstuffs – it is safe to drink in Germany.

However, it does not meet the requirements of FINESTFOG air humidification: Magnesium and calcium – the hardness formers in water – lead to calcification. In addition, the minerals do not evaporate but precipitate. The consequences are high dust pollution and clouding of the air.

FINESTFOG water treatment systems provide a solution by producing almost salt- and bacteria-free pure water.

Maximum hygiene thanks to advanced water treatment technology

FINESTFOG water treatment systems produce ultra-pure water – virtually free of salts and bacteria. A closed water circuit, high-quality membranes, regular flushing of the entire system, and effective UV light irradiation produce water that is hygienic and technically impeccable.

Efficiency improvement through intelligent control in water treatment

Control increases profitability. FINESTFOG Water Treatment provides information about the key parameters at a glance: The quantity of produced purified water or waste water is immediately visible. The conductivity is constantly monitored. The system will alert if the desalination rate is too low. The remaining service life of the UV lamp is displayed digitally. Operating states can be transmitted.

Optimisation through synergies: Water treatment and air humidification hand in hand

FINESTFOG modules are compatible with each other. The ideal combination is a FINESTFOG water treatment system with a FINESTFOG air humidification system. The water treatment is controlled and monitored by the air humidification system. Alternatively, there is the stand-alone solution: a reverse osmosis system with integrated Eaton control and touch display produces completely autonomous purified water for any application.

Reverse osmosis

The compact reverse osmosis systems from FINESTFOG impress with their open design and performance. The systems produce between 100 and 900 litres of pure water per hour (larger systems available on request).

The is the centrepiece of the pure water system is the FINESTFOG osmosis module. The high-quality spiral wound membrane inside is specialised for high efficiency and long lifespan.

The open design offers optimum control. Flow meters for permeate and concentrate provide information on treatment efficiency. A conductivity sensor ensures the highest water quality. Thanks to the pre-alarm and alarm, too high a conductivity value cannot lead to problems. All operating parameters can be called up via the touch display. The operator receives information about the operating status via a remote fault signal.

The closed system with only a small water supply prevents water contamination. An integrated sterilisation system provides the rest of the safety. It protects against germs and bacteria by irradiation with UV light at the end of the process.

Water softening systems

Compact, ready-to-use and electricity-free – that’s how FINESTFOG water softening technology works. Tap water flows through a column filled with cation exchange resin. Magnesium (Mg2+) and Calcium (Ca2+) ions are exchanged for an equivalent amount of Sodium (Na+) ions. The resulting softened water now contains more sodium salt (table salt) but hardly any magnesium and calcium. Both are known as hardness builders. Exhausted exchange resin is automatically regenerated using regenerating salt from the storage tank. In air humidification systems, sodium ions prevent the nozzles from calcifying and clogging. In reverse osmosis systems, water softening systems are used for pre-treatment of the process water.

FINESTFOG water softening systems are always pendulum systems with two resin columns. This ensures availability of soft water at all times. Regeneration is volume-controlled: it only takes place when the resin column is actually exhausted. This saves salt and waste water. An electronic salt deficiency indicator (optional) indicates when the regenerating salt is depleted.

Dosing technology

FINESTFOG supplies compact, ready-to-connect water treatment technology for print shops. In addition to the supply of humidifiers, the fountain solution supply for printing presses is becoming increasingly important.

The centrepiece of a FINESTFOG pure water system is the high-quality wound membrane, which specialises in high efficiency with a long service life. The pure water obtained in this way is to the exact desired water hardness using the fine adjustment on the doser. The benefits in the printing process are enormous:

- Fluctuations in the quality of tap water are compensated

- Running dry of the ink rollers and the deposition of lime in dampening or ink units is prevented

- Longer service life of the ink rollers

- The pH value is kept neutral

- The need for alcohol can be significantly reduced

- Germ-free purified water prevents clogging of the dampening system by micro-organisms

- Adequately large pressure storage even with complete refill of the dampening water

UV disinfection

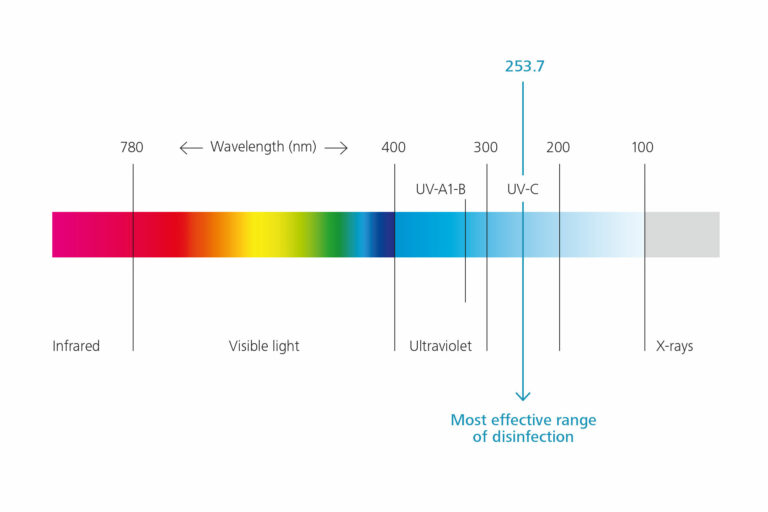

Optimal prophylaxis: The high-intensity UV sterilisation protects against bacteria, viruses, germs and legionella. The compact design of the UV sterilisation system is ideal for filtration directly at the point of use.

The pure water stored in the storage tank flows through the UV disinfection system before the water is pressurised by the high-pressure pump.

The high-performance UV lamps reduce bacteria and viruses by 99.9% – making them particularly suitable for the highly effective purification of humidifier water. Irradiating the water with intensive UV light largely prevents the formation of germs and bacteria.

Other features:

- Flow rate 225 - 1,800 litres per hour

- Stainless steel working chamber, polished, for laboratory and medical applications

- Audible alarm and LED lamp failure indicator

- The day counter on the system's touch display shows how long the spotlight will continue to work effectively

- 7-year guarantee on stainless steel working chamber

Frequently asked questions (FAQ)

What role does water treatment play in air humidification?

FINESTFOG humidifiers atomise the water as it is. Tap water contains minerals (magnesium and calcium) as well as any particles from water pipes or filters. These components can block the high-pressure nozzles of the humidifier. Additionally, the minerals result in unacceptable dust accumulation in the rooms. For this reason, it is imperative that pure water is produced from the tap water by the reverse osmosis system.

Are there also standalone solutions for other applications?

In addition to supplying FINESTFOG humidifiers, FINESTFOG osmosis systems also produce pure water for other applications. Standalone systems have their own control unit (Eaton E4) with touch display. All operating parameters such as conductance, pump pressure, UV lamp runtime etc. can be read off the touch display.

How do FINESTFOG water treatment systems ensure hygienically safe water?

The water pressure is increased to approx. 6-8 bar by the pump and channelled through the membrane. All particles are filtered out there. In addition to minerals, also viruses, bacteria and other impurities. The water after the membrane is highly pure. Regular rinsing of the membrane, the closed water circuit and effective irradiation with UVC light ensure that the pure water remains in this condition until it is used.

How does FINESTFOG monitor hygiene and is this documented?

FINESTFOG technicians take water samples from the systems as part of the maintenance contract. Our technicians are all certified in accordance with VDI 6022 sheets 1, 4 and 6 and are authorised to carry out hygiene checks on FINESTFOG systems. An independent laboratory analyses the water samples and sends the results to the operator in writing. This allows the operator to document continuously how hygienically sound their FINESTFOG air humidifiers and water treatments operate.